LIDAR Solves Critical Engineering and Construction Challenges in Airport Renovations

Today, one of the most valuable construction techniques in airport renovations is the usage of digital twins before any construction begins. Incorporating 3D scanning into airport renovations offers a wealth of benefits, potentially saving millions of dollars by directly reducing construction and operating costs.

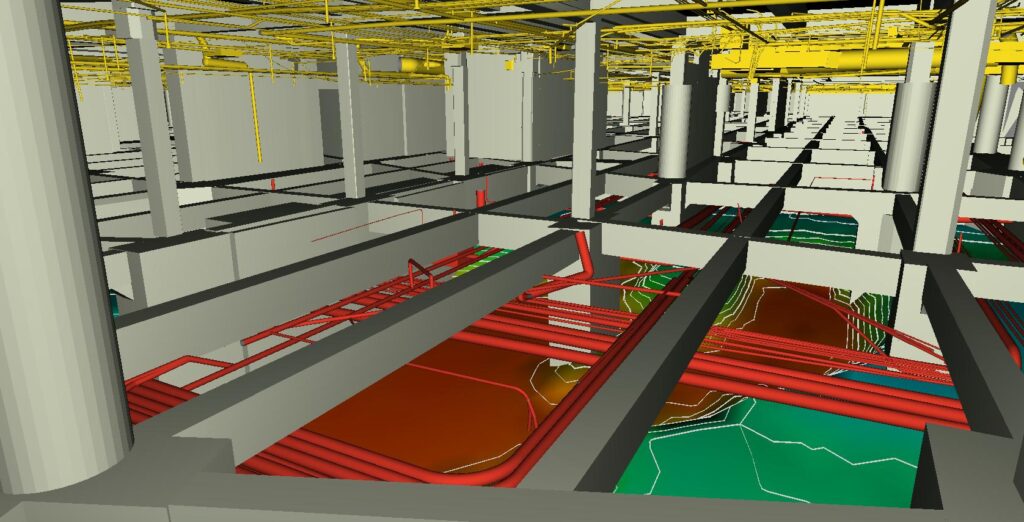

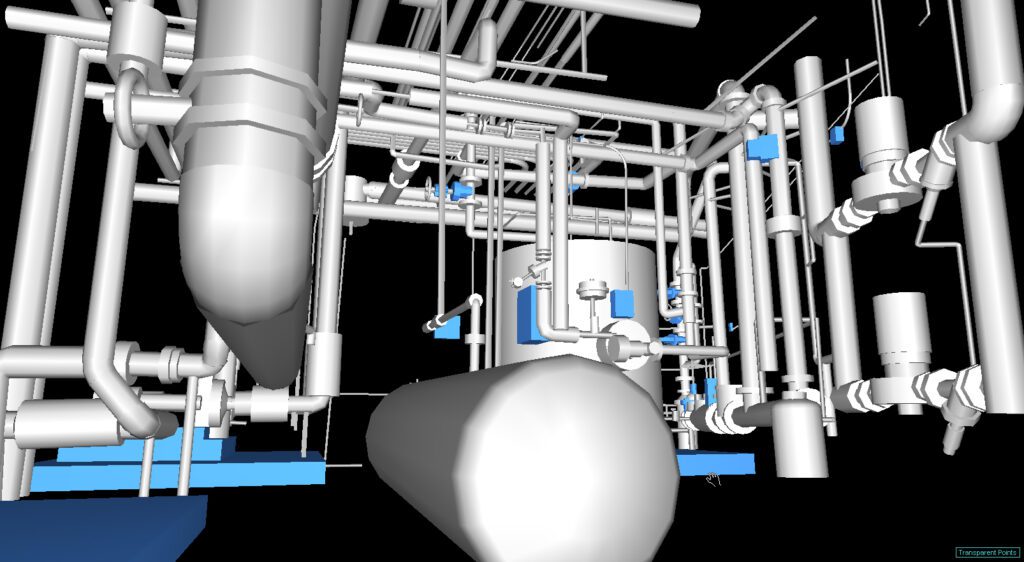

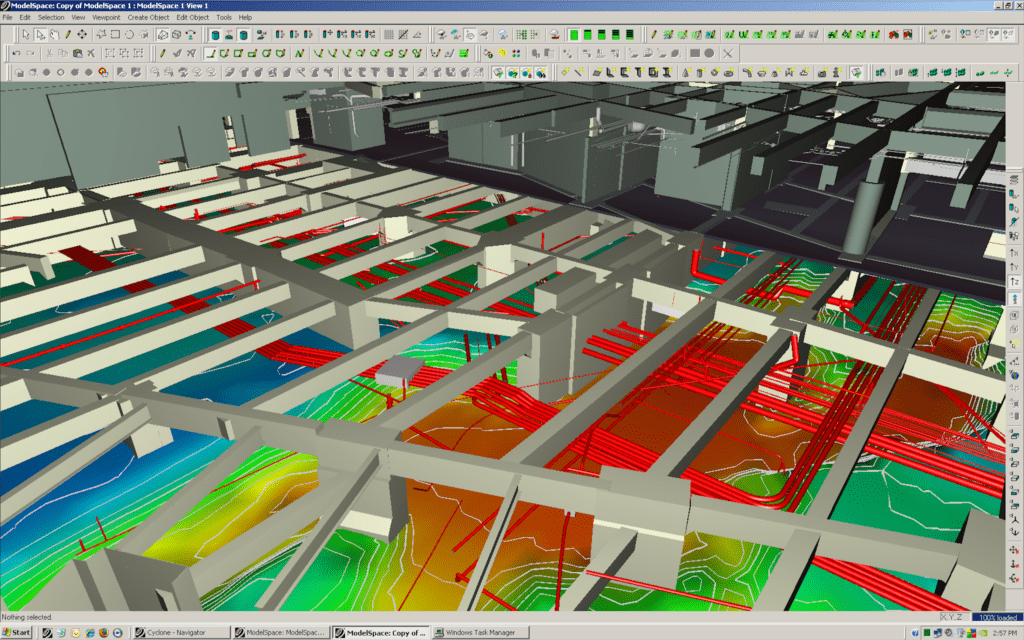

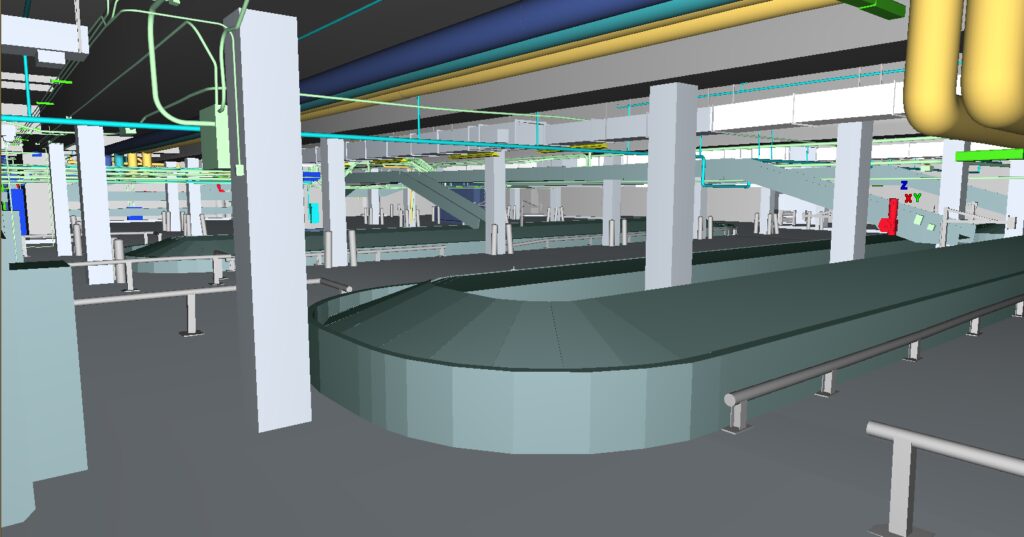

Utilizing the data from the as-built 3D digital twin provides your team with a complete model of all existing visible structural steel, MEP and equipment. This baseline data can be used by the engineers, architects and construction contractors at the same time, without each contractor going to the site to take measurements. As the renovation design plans progress, potential clashes can be visualized and avoided. Construction companies that utilize digital twins can boost their ROI through increased collaboration with airport personnel and all contractors, which lowers risk.

Project Facts

Project: Airport Construction, Renovation and Expansion

Client: Various

Project Locations: Phoenix (PHX), Dulles (IAD), Tucson (TUS), San Francisco (SFO)

Industry: Airports

Technology Used: Ground-based LIDAR

Deliverable: Revit

Accuracy: +/- 0.5 inch/6mm (ground-based LIDAR)

Key Challenges

- Lack of measurable up-to-date as-built data for renovations/expansion

- Identify discrepancies, reveal infrastructure anomalies, discover out-of-spec installations

- Identify potential crash detection issues

Solution

Darling Geomatics performed 3D laser scanning and surveying on two levels of an international airport terminal that was being reconstructed to produce digital as-builts of exterior and interior of all relevant structures and topography. The end result was a highly accurate and detailed Revit model that saved 60 days in design time.

Benefits:

- Saved sub-contractor 60+ days of design time

- Increased safety by eliminating dangerous manual measurements

- Maintained normal airport operations during scanning

- Easily shared georeferenced measurement data across all sub-contractors

- Improved construction coordination

- Reduced insurance costs

- Verification of subcontractor work

- Eliminated rework and delays

- Accurate as-built project documentation used for maintenance, inspection and future renovations

- Streamlined project workflow

- Monitor construction progress in 3D

- Confirm code compliance during and after construction

Additional Information